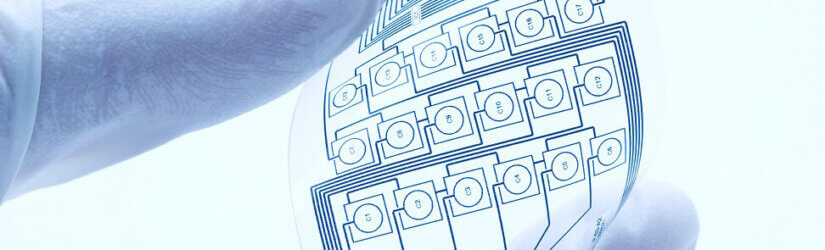

A flexible printed circuit, or FPC for short, is simply a circuit on a thin flexible substrate with conductive traces. It may have surface mount devices (SMD) like LEDs and resistors, and it typically has a termination point or connector for integration with other components. Think of a flex circuit as a printed circuit board (PCB) that can bend. However, in reality, there are significant differences in terms of design, manufacturing methods, and functionality, so it’s important to use the right substrate for the application. Read more “What Are Flexible Printed Circuits?”