Polymer vs Plastic

What is a polymer? What are plastics?

Here is a simple explanation of the difference between polymers and plastics.

Read more “Polymer vs Plastic”

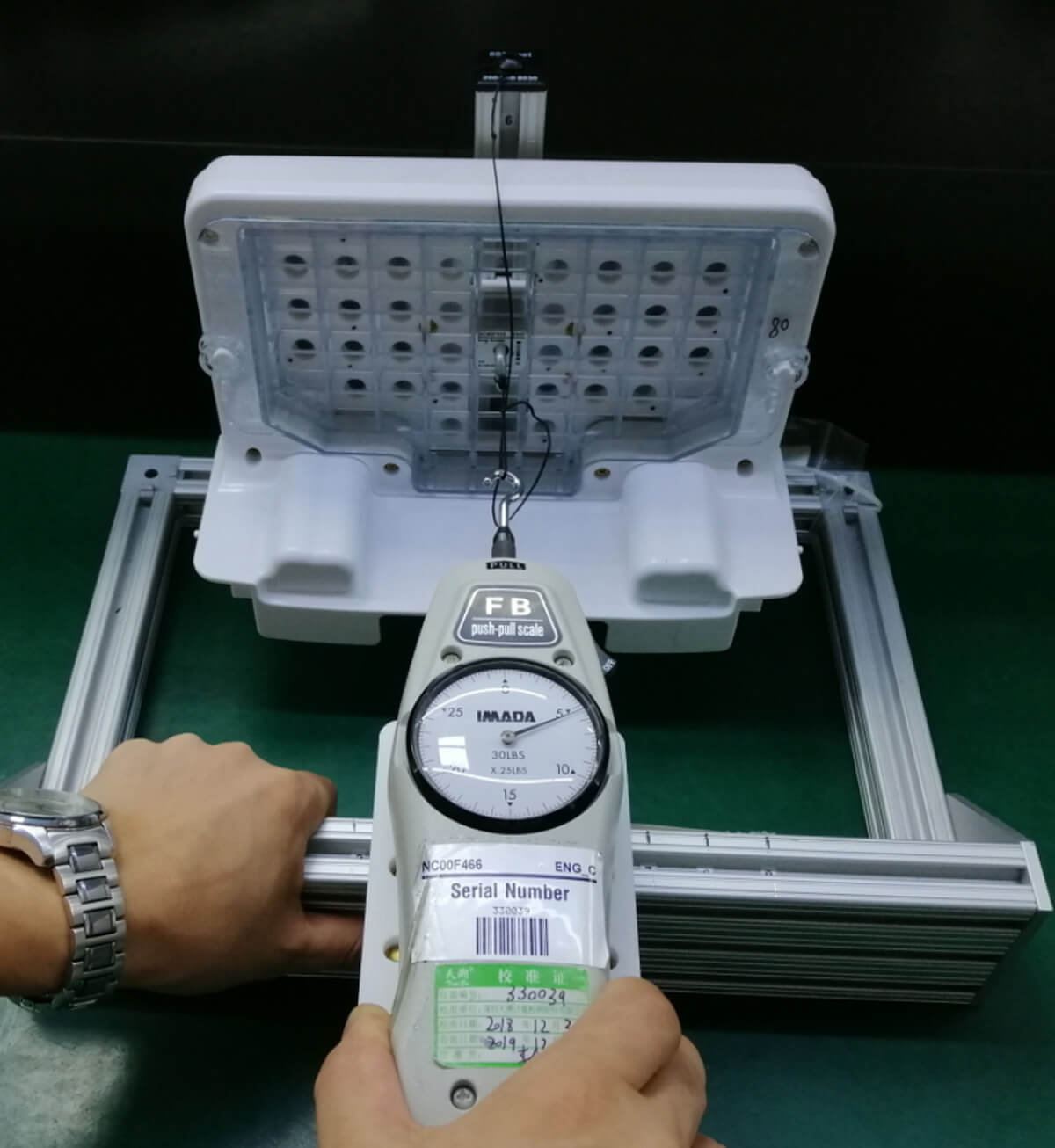

RSP’s Testing Systems

What We Do To Ensure High Quality All The Time

RSP utilizes testing equipment to qualify the products we manufacture during design and production. Read on to learn more about some of the equipment we use to ensure our customers’ products work for the environment they will be used in.

Read more “RSP’s Testing Systems”

End-to-End Solutions Provider

Assistance From Design to Fulfillment

RSP can assist our clients in every area of the product development cycle from design and engineering to prototyping to pre-production ramp-up, production, logistics and transportation, warehousing and order fulfillment. Let’s take a deeper dive into what each of these areas means and how RSP can help.

Read more “End-to-End Solutions Provider”

Developing & Building Outdoor Products to Last

During the summer months, outdoor enthusiasts venture outside to enjoy Wisconsin’s plentiful lakes and diverse wilderness. Oftentimes this means boating, bike riding, archery, target shooting, ATV riding, fishing and more! Read more “Developing & Building Outdoor Products to Last”

Indicator Light Standards for Membrane Switches: Indicator Colors

There are several different standards when it comes to indicator lights on membrane switches and printed circuit board assemblies (PCBA). Here are some standard color designators.

Read more “Indicator Light Standards for Membrane Switches: Indicator Colors”

Featured as ‘Best of the United States’

Vision Mag Highlights RSP

We are humbled and honored to be featured in the ‘Best of the United States’ section of Vision Mag. Read more “Featured as ‘Best of the United States’”

UV Nitrogen Hard Coat Textures for Membrane Switch Applications

Top-Quality Membrane Switch Coatings

In the 1990s the demand for durable, scratch- and chemical-resistant UV coatings reached its peak. The best method for producing these coatings required curing specialty inks in an inert, oxygen-free atmosphere, and so the UV nitrogen dryer, which floods the environment with nitrogen, became the equipment of choice. Many UV nitrogen dryers also incorporated plasma bulbs at the head of the dryer that cured the very top layer of ink to create a skin that could be controllably wrinkled to varying degrees, offering a wide variety of surface textures from a single ink. Read more “UV Nitrogen Hard Coat Textures for Membrane Switch Applications”

Contract Manufacturing FAQ: Answers from the Experts

Let’s Hear from the Sales Team

Frequently Asked Questions (FAQs)

Our clients, especially those with projects where multiple components are used in an assembly, ask us thoughtful, probing, and challenging questions every day. Often, these questions are very particular to a custom product we manufacture (e.g., “How will hot runners affect my plastic molding?”). Other times, the questions apply to almost any customer! Here is a sampling of some of those frequently asked questions that apply to most projects. Read more “Contract Manufacturing FAQ: Answers from the Experts”