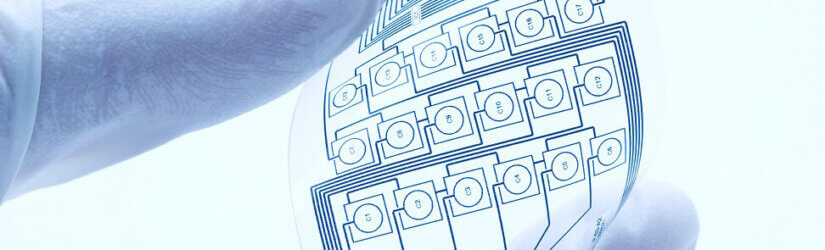

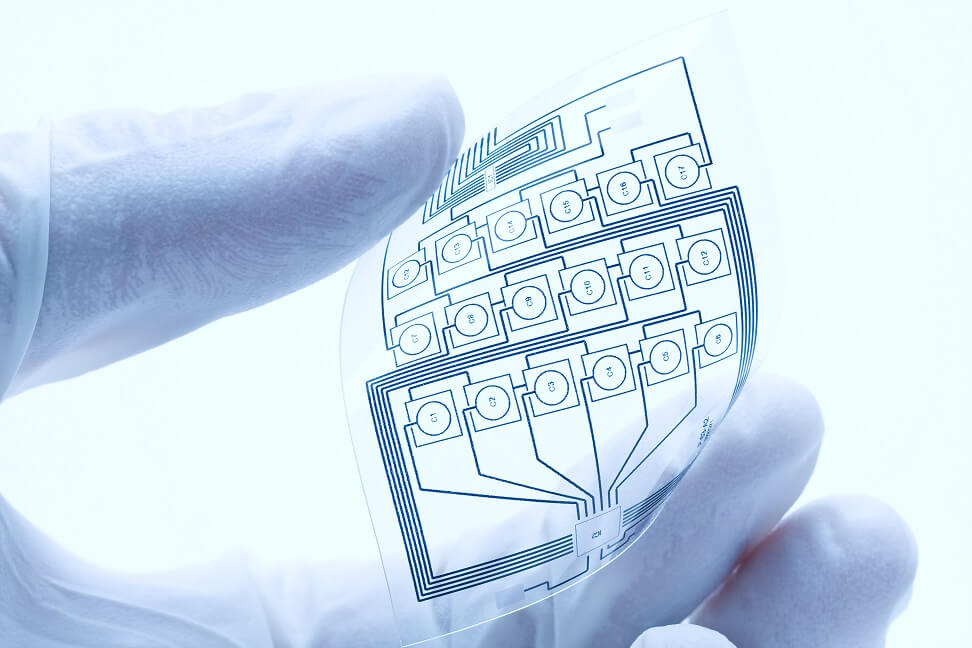

A flexible printed circuit, or FPC for short, is simply a circuit on a thin flexible substrate with conductive traces. It may have surface mount devices (SMD) like LEDs and resistors, and it typically has a termination point or connector for integration with other components. Think of a flex circuit as a printed circuit board (PCB) that can bend. However, in reality, there are significant differences in terms of design, manufacturing methods, and functionality, so it’s important to use the right substrate for the application.

Flexible Substrate Options

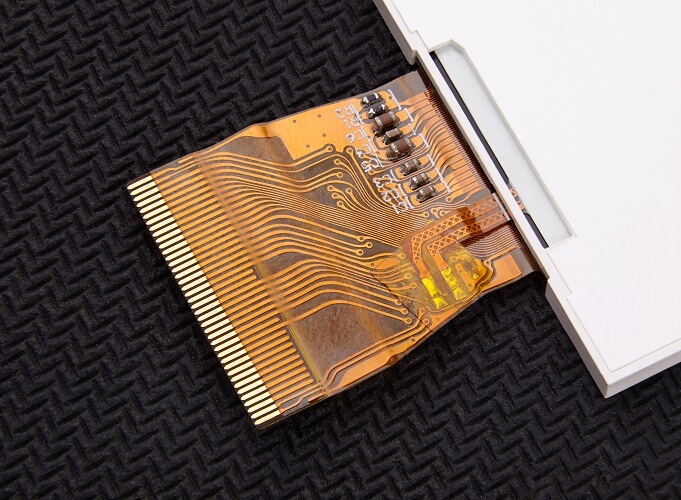

There are two main substrates used in the flexible printed circuits manufacturing process. One of the original materials used that is still common today is flexible polyester film. With this material you typically screen print conductive traces or circuits using a silver-based ink, which limits the layers and scale you can achieve. Polyester substrate is typically .002” to .005” thick, with less range of thickness than polyimide substrate. However, polyester is still a great option today when there is available space, the circuit is not very complicated, and there are not many surface mount devices.

For more technical requirements, polyimide or copper flex circuitry is used. The traces and circuit are produced using photo imaging or laser imaging rather than printing. A polyimide circuit consists of a metallic layer of traces that are bonded to a dielectric layer. To prevent the copper from oxidizing, the exposed surfaces are covered with a protective layer of gold or solder.

Applications of Flexible Printed Circuits

Whether they are the primary circuit or used to connect to components, flexible printed circuits are found in almost every electronic device. For example, a camera might use one or more rigid printed circuit boards for the main components and controller. However, the interface between the rigid board and a USB connector would probably be a flexible printed circuit so that the connector can be located anywhere on the camera and does not need to be mounted directly on the rigid board. Given the small scale of a camera, a polyimide rather than a polyester substrate would probably be used.

Another example would be VR gloves. The rigid controller board might be mounted on the glove around the wrist, but the fingertip sensors could be connected to the rigid board with flexible printed circuits so that the fingers can move freely and the circuit can “flex” naturally. Since the circuit is subject to repetitive motion, printed silver traces on polyester would not be the best choice. Instead, a polyimide circuit would be the correct choice to avoid the risk of cracking when the gloves are worn.

Applications that are static and have available space, like a keypad on a microwave oven or the circuit under an ATM keypad, are examples where polyester circuits are commonly used.

Costs of Manufacturing Flexible Printed Circuits

The cost of producing circuits on polyester is lower than the cost of polyimide circuits when the dimensions and functions are similar. However, the limitations on polyester flex circuits allow them to be used only in limited applications, so often cost is not a consideration in deciding the type of circuit.

Why Choose RSP?

RSP has been manufacturing flexible printed circuits since the 1980s. Over the past four decades, we have made millions of flexible printed circuits that are used in medical devices, in consumer and industrial products, in the automotive industry, and everywhere else! You have probably used or seen at least one of our flexible circuits in some device.

With our global operations supplying products to over 40 countries and thousands of clients, RSP has the experience and expertise you need to get the job done right. If you need to make these flex circuits, contact us today to make RSP your flexible printed circuit board manufacturers.