Custom Membrane Switch Manufacturer

RSP is a trusted manufacturer of membrane switches with operations in the US and China. With years of experience under our belt, we have honed our craft in creating custom membrane switches that cater to diverse industry needs. From industrial equipment to consumer electronics, we have the knowledge and expertise to deliver exceptional results. Ready to explore the potential of membrane switches and embark on a partnership with RSP as your custom membrane keypad manufacturer? Contact us today to learn more about our production process and how we can bring your ideas to life with precision and excellence.

What are membrane switches?

Membrane switches, also known as membrane panels or membrane switch keypads, are electrical switches with a graphical user interface to control equipment and machines. Unlike their bulkier mechanical switch counterparts, membrane switches utilize a thin circuit layer (more on that below) to efficiently carry electrical signals. With their flexible nature and low-profile design, membrane switches offer endless possibilities for various applications. From household appliances like microwaves and air conditioners to everyday essentials like remote controls, custom membrane keypads and switch panels have become an integral part of our lives.

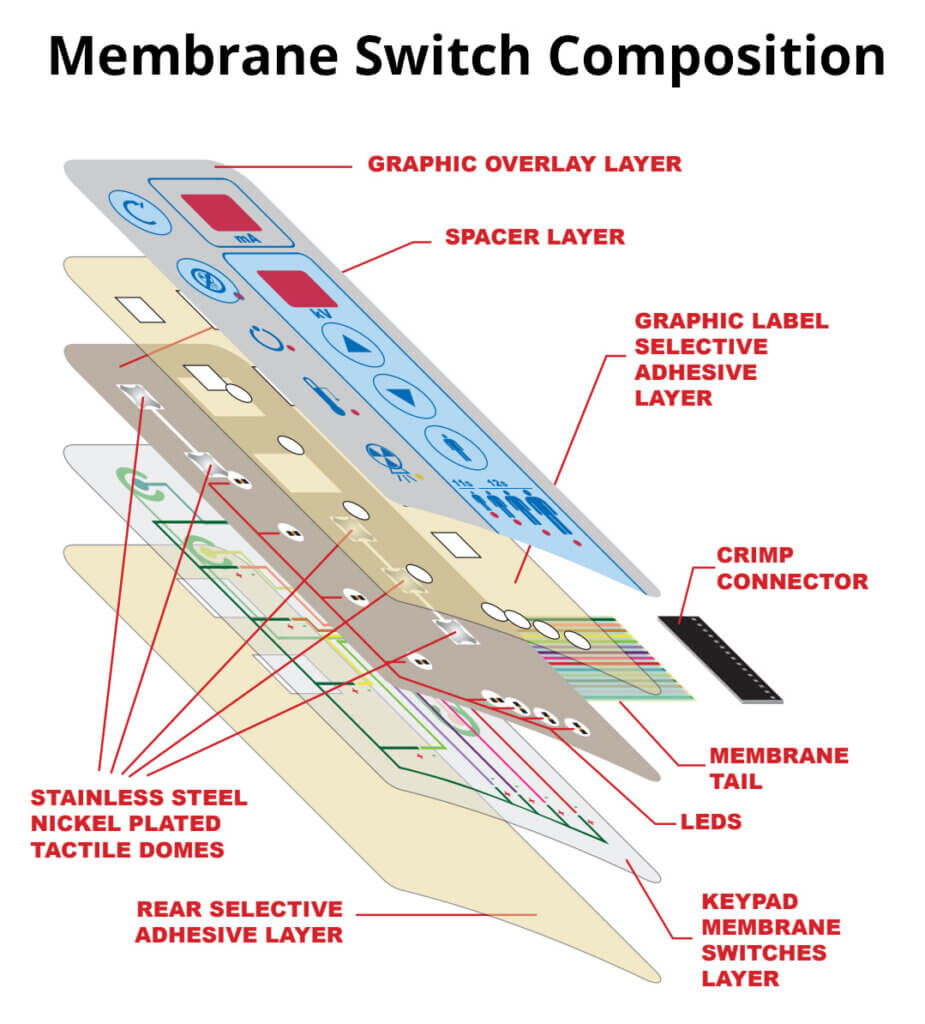

Components of Membrane Switches

Despite their thin profile, membrane switches are actually composed of 6-8 layers of thin film and adhesive. Each layer plays an important part in the overall function and performance of the membrane switch.

Graphic Overlay

The top layer of a membrane switch is the graphical user interface, often referred to as the graphic overlay. This layer uses icons or text to visually communicate the functions controlled by the switch. A well-designed graphic overlay is crucial for ensuring an intuitive user experience.

Dome Spacer Layer & Adhesive

When a membrane switch incorporates tactile metal domes, a spacer layer with adhesive is positioned beneath the graphic overlay. This layer not only provides spacing for the metal domes to actuate but also acts as a bonding element, securing the circuit to the graphic overlay.

Circuit Layer

The circuit layer is where the real magic happens. Conductive inks are carefully applied to a plastic substrate using a silk-screen printing process. In certain cases, additional insulating layers may be required to safeguard the circuit against static discharge, ensuring optimal performance.

Spacer Layer

For membrane switches without tactile metal domes, a spacer layer is typically incorporated. Made of polyester, this layer acts as a barrier between the upper and lower circuits. When pressure is applied to the graphic overlay, the two circuit layers are brought together, effectively closing the switch.

Adhesive Layer

To finalize the construction of the membrane switch, an adhesive layer is applied to the rear of the circuit. This adhesive layer securely bonds the switch to the bezel or substrate, contributing to the switch's durability and extending its overall lifespan.

Understanding the intricacies of each layer in a membrane switch enables manufacturers to create reliable, user-friendly interfaces. From the visually engaging graphic overlay to the essential circuit layer and the critical adhesive elements, each component plays a vital role in delivering a seamless user interaction.

Haptics

When it comes to delivering an exceptional user experience, membrane switches shine by offering a combination of haptic and visual feedback. These dynamic features enhance user interaction and ensure a seamless interface. A great example of a haptic feedback mechanism is the use of tactile metal domes or poly-dome construction. Users feel a satisfying "snap" or responsive touch as the dome is compressed, creating a tangible and engaging experience.. The key might also provide some audible feedback from the “snap” of the dome. Membrane switches excel in visual feedback options as well. Integrated LED indicators or embedded light guide film strategically positioned within the switch, enable users to easily identify activated functions, modes, or status updates. The visual cues enhance clarity, intuitiveness, and overall user satisfaction.

By combining haptic and visual feedback, membrane switches empower users to interact with confidence and efficiency. Whether it's the reassuring tactile response or the clear visual cues, these features contribute to a memorable and user-friendly interface.

Benefits of Membrane Switches

Membrane switches' slim profile and flexibility make them highly adaptable for various product designs. Their low-cost nature ensures affordability without compromising on quality, making them an economical choice for manufacturers and users alike. With their intuitive design, users can effortlessly navigate functions and controls. Additionally, their durability allows them to thrive in diverse environments, resisting moisture and dust ingress. This resilience extends the product's lifespan, enhancing its value.

As a leading membrane keypad manufacturer, RSP specializes in crafting graphic overlays tailored to your specific needs. This customization enables optimization of the user interface, ensuring a seamless and intuitive user experience. The right blend of colors, icons, and text on the graphic overlay elevates usability and enhances user satisfaction.

With their enclosed design and resistance to external elements, membrane switches excel in reliability and longevity. They unlock endless possibilities for industries ranging from consumer electronics to medical devices.

Which Industries Use Membrane Switches?

Membrane switches can be created for a variety of industries and environments. Some common uses are in appliances, consumer products, industrial machinery, medical instruments and automotive industries.

Creating a Membrane Switch with RSP

At RSP, we understand the critical role of proper design in creating exceptional membrane switches. We pride ourselves on our involvement in every stage of the development process, collaborating closely with our customers to bring their ideas to life. Here's how we make it happen:

Transforming Ideas into Reality: Our development process begins with a customer's vision, which can range from a simple sketch on a napkin to a verbal description or even a production file. Regardless of the starting point, our experienced team is adept at interpreting and translating ideas into functional membrane switches.

Customer-Centric Approach: To ensure a seamless collaboration, we encourage customers to provide their desired graphics and a description of how they plan to connect the circuit to their device, known as a pinout. Armed with this information, our skilled engineers create the circuit layout and intricate details, precisely aligning the switch with the customer's requirements.

Iterative Design Process: We believe in the power of iteration and feedback. Throughout the development phase, we work closely with our customers, incorporating their input and refining the design until it meets their exact specifications. This iterative approach ensures that the final membrane switch perfectly aligns with their needs and delivers an optimal user experience.

By leveraging our expertise in membrane switch design and production, we transform concepts into tangible solutions that exceed expectations. From graphics to circuitry, RSP combines precision and innovation to create membrane switches that elevate user interfaces across various industries.

When it comes to membrane switch design, a range of important factors must be taken into account to ensure optimal performance and user satisfaction. Here are some additional considerations that RSP focuses on:

- Actuation and Durability: Understanding the number of actuations required is crucial for designing a reliable membrane switch. Whether it's a high-traffic interface or a specialized application, our team evaluates the expected usage and selects materials and construction techniques that guarantee longevity and robustness.

- Environmental Factors: Membrane switches often find themselves in challenging environments, from dusty industrial settings to high-humidity conditions. By considering the intended usage environment, we select materials and implement sealing techniques that protect the switch from moisture, dust, and other external factors, ensuring reliable performance in diverse surroundings.

- User Experience: We take into account how the switch will be used and who will be operating it. Factors such as operator presence, glove usage, and ergonomics are carefully evaluated to design a switch that delivers a seamless and comfortable user experience, enabling smooth and efficient operation.

At RSP, we strive to provide accurate and competitive quotes for your membrane switch needs. To ensure a seamless and efficient quoting process, it's important to provide us with the following information:

Dimensions: Please share the precise dimensions of the membrane switch, including length, width, and any specific shape considerations.

Colors and Materials: Let us know the number of opaque and/or transparent colors needed for your graphic overlay. Additionally, specify your desired top layer material, or rely on our expertise to guide you in choosing the ideal option that balances aesthetics and functionality.

Adhesive Requirements: Inform us about the adhesive requirements for both the top and bottom layers of the membrane switch. This ensures proper bonding and durability in your specific application.

Embossing: If you require raised keys or other embossed features, provide us with details about the type and extent of embossing you desire. Embossing keys can add tactile feedback and enhances the user experience.

Keys and LEDs: Let us know the type and number of keys required, whether tactile, domes, or flat. If you require LEDs, specify the desired quantity and colors for optimal visual impact. Additionally, inform us of any backlighting requirements, such as LEDs or light guide film, to ensure proper illumination.

Connector Type: Share the type of connector needed for your membrane switch, ensuring seamless integration with your device or equipment.

Quantities: Provide us with the desired quantity of membrane switches needed. This information helps us offer competitive pricing and plan for efficient production.

By furnishing us with these essential details, you enable us to deliver accurate quotes and craft membrane switches that precisely meet your specifications. RSP's expertise and dedication to customer satisfaction ensure a seamless collaboration throughout the entire process.

Starting a new membrane switch project can feel overwhelming, especially with the multitude of options and considerations involved. But fear not! At RSP, we're here to provide you with expert guidance and support, ensuring a smooth and successful journey from start to finish.

Mounting Membrane Switches

After the creation of membrane switches, a critical step in ensuring their longevity and functionality is their proper mounting or assembly onto the equipment or machines they control. Prior to mounting, the switches can be susceptible to damage if not handled with care. To safeguard your membrane switches and prevent any potential mishaps, it's crucial to follow the specific mounting instructions provided. A copy of the instructions is included below.

We understand that every application is unique, and to further assist our customers, we also offer an additional service. If desired, you have the option to send your enclosures to RSP for professional assembly of the membrane switches. Our experienced team will expertly mount the switches onto your enclosures, ensuring precision and minimizing any potential risks of damage. RSP also offers custom made enclosures and bezels, providing you with a convenient one-stop shopping experience. Whether you require enclosures made from plastic or metal, our skilled team is well-equipped to meet your specific requirements.

Request a Quote

If you are like any of our customers, you think about your product 24/7. You dream of how it will change the market or maybe you’re creating a brand new market. But when it comes to executing the product, you’ve realized you need some help. And that’s where we come in.

Fill out the information below so we can get a good understanding of what you may need from us. We will respond as quickly as possible to your request, however, please allow at least 24 business hours.

Looking for immediate assistance? Call our sales professionals directly based on the timezone that works best for you. English speakers are available at all locations.

USA: +1-866-329-1804 - UTC-6: Central Standard Time

China: +86-0755-8366-3414 - UTC +8: China Standard Time