Prototyping services have become an essential element in the modern product development process. As industries evolve, the gap between initial design concepts and mass production widens, necessitating an intermediary phase where ideas can be tested and refined. This blog explores how prototyping services play a crucial role in transforming innovative designs into manufacturable products, ensuring both functionality and market readiness.

Understanding the Role of Prototyping in Modern Industry

The significance of prototyping services cannot be overstated in today’s fast-paced industries. They act as a crucial step between design and production, providing an opportunity to test the functionality, aesthetics, and usability of a product before it hits the market. For instance, by collaborating with RSP Inc., companies can seamlessly transition from idea to design, ensuring their innovations are manufacturable and ready for market entry.

Prototyping allows companies to visualize a concept in tangible form, making it easier to assess potential design issues early in the development stage. This tangible nature aligns stakeholders, providing a clear representation of the envisioned product. Through iterative development, prototyping validates the design, permitting necessary alterations while minimizing costly mistakes in later production phases.

Moreover, prototyping facilitates the establishment of realistic expectations among stakeholders, suppliers, and investors. This is especially crucial when innovating in highly competitive markets where time-to-market is pivotal. Through services like RSP’s prototype manufacturing, companies can realize their concepts with precision, paving the way for effective communication and alignment across teams, thereby enhancing decision-making processes.

The Prototyping Process: From Concept to Creation

Prototyping begins with conceptual sketches that translate initial ideas into basic formations. Designers progress to creating detailed models, often utilizing methods like computer-aided design (CAD). Throughout these stages, potential flaws are addressed, ensuring the design’s feasibility. Each stage of prototyping is a crucial step in product readiness, as it allows for functional verification and adjustment prior to mass production.

As development advances, teams move to fully functional prototypes that operate akin to the final product. This pivotal phase allows for real-world application testing, offering insights into product adaptability and usability. By integrating prototypes into testing environments, companies can capture valuable user feedback and make necessary modifications, establishing a foundation for customer satisfaction and loyalty.

RSP’s Product Design & Prototyping services exemplify this process. By leveraging design capabilities, the focus remains on creating innovative products that are ready to conquer the market efficiently. This structured approach minimizes uncertainties, reduces lead times, and increases market potential for new inventions.

Technological Advancements Enhancing Prototyping

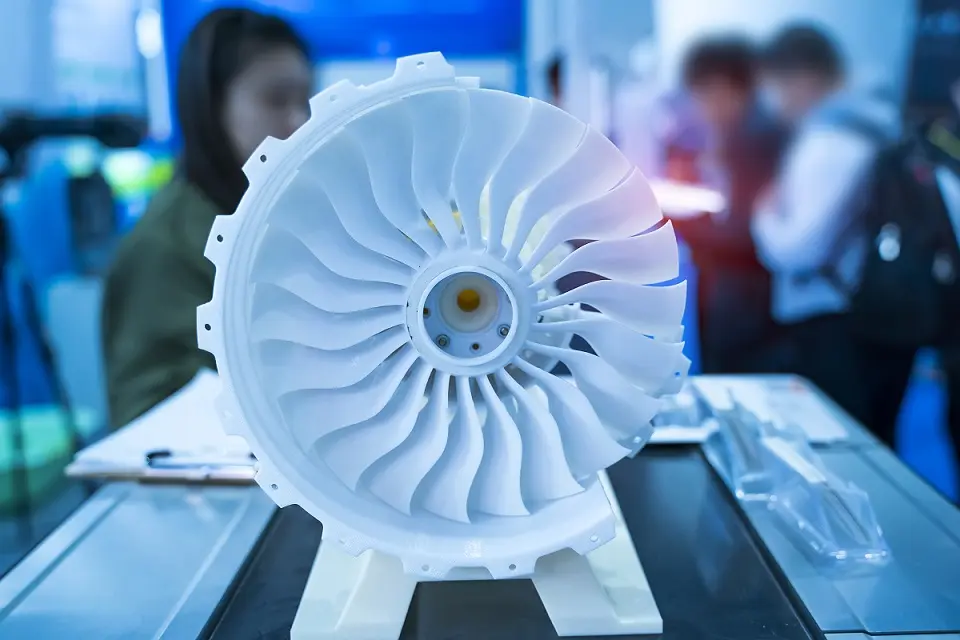

Recent technological strides have significantly enhanced the prototyping landscape. Advancements in 3D printing, for example, have enabled faster and more accurate prototype creation. Companies like Stratasys are streamlining this process, allowing designers to quickly iterate on their concepts and refine ideas in rapid succession, thus shortening the path from design to final product.

3D printing isn’t just expediting the prototyping phase; it’s revolutionizing it by providing unprecedented flexibility. Designers can now effortlessly switch between different materials and adapt prototypes based on real-world testing outcomes. This adaptability offers immense room for creativity, leading to better-informed decisions and a final product that resonates superbly with market demands.

Moreover, the advent of immersive technologies such as virtual and augmented reality is redefining prototype evaluations. These tools allow designers to experience and test their creations in simulated environments, gaining deeper insights into user interactions and needs. This not only accelerates the identification of design efficiency but also enhances customization, ensuring the end product is perfectly aligned with user expectations.

Challenges in Prototyping and How to Overcome Them

Despite its numerous advantages, prototyping is not devoid of challenges. One significant hurdle is the cost of materials, which can escalate if not managed judiciously. Additionally, time constraints often pressure designers to expedite processes, sometimes at the expense of detail and thoroughness. Success in prototyping requires strategic planning and efficient resource allocation to stay aligned with budgetary and timeline restrictions.

Specialized skills are paramount in prototyping, demanding a workforce equipped with relevant training and expertise. This calls for ongoing education and investment in skill enhancement to maintain competitive edge. By collaborating with proficient partners like RSP, companies can tap into established expertise to streamline their processes and focus on design innovation without worrying about underlying technicalities.

Furthermore, effective communication is essential to address these challenges. Transparent information exchange between teams and stakeholders fosters a collaborative environment, where potential issues can be identified and resolved promptly. Regular feedback loops ensure prototypes are continuously refined, leading to a seamless transition from conception to market-ready products.

The Future of Prototyping Services in Product Development

As we look into the future, the role of prototyping services in product development is set to expand exponentially. With increasing demand for rapid innovation and customized solutions, prototyping will become the linchpin of successful product lifecycle management. Integrating emerging technologies like artificial intelligence (AI) and the Internet of Things (IoT) could further streamline this process, providing unprecedented accuracy and responsiveness.

Automation will play an integral role, allowing faster iterations with minimal manual intervention. By reducing repetitive tasks, designers will have more time to focus on refining concepts and infusing creativity into products. Ultimately, this innovation wave will not only accelerate product development cycles but also elevate the quality and diversity of solutions offered to consumers.

The future promises a more integrated approach, where prototyping becomes part of a continuous feedback loop extending well beyond the initial product launch. Maintaining adaptability will prove crucial as companies strive to cater to evolving consumer needs and market trends, fostering a culture of continuous improvement and innovation.

Final Thoughts on Prototyping Services

In conclusion, prototyping services serve as a critical bridge that connects visionary design concepts with practical production capabilities. Through iterative testing and refinement, they ensure that products not only meet design specifications but also cater to market needs. As technology continues to advance, the importance of prototyping in product development will only continue to grow, offering invaluable insights to designers and manufacturers alike. To learn more about our prototype manufacturing capabilities, visit our homepage at RSP Inc..